Cost structure comparison: rattan vs. other furniture materials

The world of furniture manufacturing is as diverse as the materials that span it. From the exquisite grains of hardwood to the sleek elegance of metal and the versatility of plastic, every material holds a particular allure. Among these, rattan stands in its own niche, admired for its eco-friendly nature and natural beauty. The cost structures associated with furniture production pivot on factors such as the cost of raw materials, labor, durability, and long-term financial implications. As consumers increasingly gravitate towards sustainable and affordable options, understanding the intricate cost dynamics between rattan and other materials becomes essential for manufacturers and buyers alike. This article delves into the comparative costs of rattan furniture against its counterparts in wood, metal, and plastic, analyzing aspects such as initial investment, maintenance, and resale value, while considering environmental and market trends.

Cost structure of rattan furniture

The cost structure of rattan furniture presents a complex yet intriguing matrix, primarily revolving around fixed and variable costs related to its production. In exploring the nuances of rattan furniture manufacturing, understanding the investment in fixed costs such as capital expenditure, operating costs, and equipment depreciation gives insight into the financial scaffolding of the industry. Meanwhile, variable costs, which encapsulate raw materials and labor expenses, reveal the dynamic side, influenced by market demands and manufacturing scale. These cost layers contribute not only to the pricing strategies of rattan products but also to long-term financial planning and investment decisions. As rattan competes with traditional materials like wood, examining its cost advantages enhances comprehension of its place in the modern furniture market. Through this lens, we see opportunities for profitability, sustainability benefits, and market growth potential in the thriving rattan industry.

Fixed costs associated with rattan production

When delving into the vibrant world of rattan production, the fixed costs integral to the industry provide a solid backbone for understanding its economic layout. These costs, often impermeable to fluctuations in production levels, define the threshold investment to embark upon successful rattan manufacturing. Capital expenditures form the bedrock of these fixed costs, prominently encompassing the funds required for establishing manufacturing facilities, procuring essential equipment, and maintaining operational readiness. This investment hurdle is substantial, as it demands thoughtful allocation of resources toward long-lasting assets that keep the cogs of production moving seamlessly.

In seizing upon these initial investments, one cannot overlook fixed operating costs, which are the unwavering financial commitments of running a rattan production enterprise. Unyielding and consistent, these costs typically include utilities, insurance, and the salaries earmarked for permanent staff members. Together, they carve out a stable economic environment that allows for strategic planning amid the ebb and flow of seasonal demands or market variability.

A deeper dive reveals the crucial element of depreciation, where time gracefully reduces the value of machinery and equipment used over prolonged periods. This steady decline must be prudently integrated into pricing models and financial projections, ensuring that businesses remain on sure footing. Notably, licenses and permits mandated by regulatory bodies constitute an additional layer of fixed costs. These legal formalities reflect compliance with government regulations and industry standards, safeguarding the firm’s operation against potential legal or financial penalties.

Finally, investments in research and development often result in breakthrough innovations or product enhancements that give way to novel rattan designs. Such investments, though fixed in nature, allow manufacturers to capture fresh market share and respond dynamically to shifting consumer preferences. Together, these fixed costs set the stage for understanding how rattan competes with materials like wood or metal, where characteristics such as rigidity or complexity of material handling might further skew fixed cost structures.

Variable costs in rattan furniture manufacturing

Venturing into the realm of variable costs, rattan furniture manufacturing illuminates the pulsating rhythm where expenses oscillate in tandem with production volumes. Here, the spotlight centers on raw material costs, pivotal in influencing the financial equation of rattan productions. As rattan cane remains the lifeline for crafting elegant furniture, these costs vary with market availability, demand surges, and fluctuations in quality. Establishing reliable supply chains thus becomes imperative for manufacturers, ensuring they can prudently balance economic considerations against the unyielding push for sustainability.

Parallel to this, labor costs play a pivotal role. They represent a significant chunk of the variable expenditure pie, tightly correlated with the skill levels of artisans, regional wage standards, and the degree of craftsmanship intrinsic to rattan designs. With the U.S. manufacturing wages averaging around $20 an hour, specialized skills can tip the scales toward heftier sums, reflecting the symphony of expertise integral to weaving rattan into timeless art forms.

Furthermore, utility costs surmise the scene, their cadence changing with every unit produced. Industrial electricity costs at approximately $0.07 per kWh morph alongside water rates, typically spanning $1.50 to $3.50 per 1,000 gallons, encapsulating a realm where efficiency is paramount for profitability.

In orchestrating the final masterpiece, packaging and shipping expenses bring closure yet alter the cost structure significantly. Each unit typically costs $5 to $20 for packaging, with shipping adding another $50 to $200. This expense directly connects to production volumes, warranting strategic oversight and optimization to maintain lean costs. Finally, marketing and advertising costs can vary from $50,000 to $200,000 annually, aligning brand narratives with consumer values.

Long-term financial benefits of rattan investment

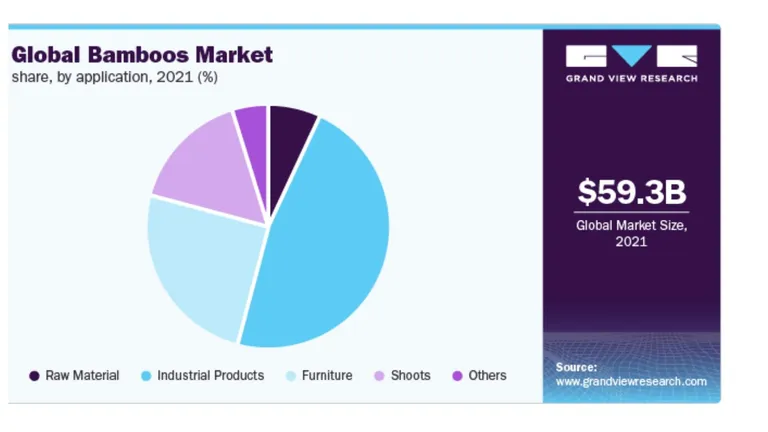

In navigating the financial tapestry of rattan investment, the lens shifts towards its long-term economic rewards. The rattan furniture industry, flourishing with a projected market growth of 6.3% CAGR to a $32 billion zenith by 2027, demonstrates ample opportunities for sustainable investment returns. This trajectory is influenced by an affinity for rattan’s eco-friendly charms, appealing to a conscientious consumer base that values sustainable living.

Rattan’s allure is further magnified by its sustainability appeal, where its inherent renewable properties resonate with eco-minded consumers. This sustainable ethos can escalate brand loyalty and reputation, carving a niche in a market ever-hungry for environmentally responsible alternatives. Rattan’s lighter burden on ecosystems positions it favorably against traditional hardwoods, setting the stage for consumer advocacy that transcends mere purchasing decisions.

Additionally, competitive pricing advantage becomes a formidable ally, where rattan’s cost-efficiency stems from its ease of harvesting and cutting-edge transportation models. These efficiencies empower manufacturers to offer competitively priced products or elevate profit margins, effortlessly straddling financial prudence and customer value. Furthermore, diversified applications buttress rattan’s long-term viability. Extensive utility spanning furniture, flooring, mats, and handicrafts broadens its scope, enhancing market presence.

Comparative cost analysis: rattan vs. wood furniture

Understanding rattan’s cost structure lays the groundwork for a comparative analysis with wood furniture, examining nuances that define each material’s economic narrative. Initial investment disparities arise from wood’s solid construction demands, swaying the financial pendulum toward heavier upfront costs compared to the relatively lower-cost rattan. The exploration of maintenance and repair expenses reveals contrasting tales, with wood’s robust nature often leading to lower cumulative expenses despite possible higher repairs. Furthermore, while wood enjoys higher resale value due to ingrained durability and a classic appeal, rattan’s charm lies in aesthetic spaces seeking trendy, light, and portable furniture innovations.

Initial investment differences between rattan and wood

When diving into the initial investment differences between rattan and wood furniture, it becomes clear that each material invites contrasting financial pathways marked by material sourcing, production methods, and anticipated maintenance expenses. Rattan often emerges as a cost-effective option, largely due to its abundance and efficient processing requirements compared to the intricate craftsmanship associated with solid wood.

The initial investment in rattan furniture is often less daunting. Rattan requires less intensive processing than hardwoods, resulting in products that are as stylish as they are lightweight, all while being more budget-friendly. On the other hand, wood commands higher initial costs, owing to the expense of obtaining quality hardwoods and the sophisticated methods necessary to treat and refine them. This higher expense threshold can present an economic burden to some, yet the perceived value of wood’s durability and aesthetic appeal often balances the scales in its favor.

Consider maintenance implications. While upfront costs for rattan tend to be lower, natural rattan’s durability wanes in outdoor environments unless adequately treated. This maintenance consideration could accumulate over time, potentially negating initial savings, especially if replacements become frequent. In contrast, wood, with its inherent resilience, often offers longevity that diminishes long-term maintenance costs, creating a favorable life-cycle cost narrative.

Analyzing aesthetics and usability, rattan’s casual yet trendy demeanor appeals across a broad consumer spectrum, serving both indoor and outdoor aesthetics with aplomb. In juxtaposition, wood stands as a testament to tradition and timeless allure, perfectly suited for formal settings. These aesthetic preferences undoubtedly shape purchasing decisions, impacting investment behavior and long-term satisfaction.

Maintenance and repair costs: rattan vs. wood

Maintenance and repair costs present another layer for discernment within the rattan versus wood debate, as each material embodies unique attributes in maintenance demand and related costs. Synthetic rattan, for instance, often shines under lower maintenance requirements due to its weather-resistant composite, proving advantageous in reducing long-term care needs. This lower requirement contrasts sharply if natural rattan is involved, necessitating vigilant care to maintain structural integrity against environmental exposure. Here, synthetic pieces may hold their charm for five to seven years, potentially reaching a decade with fastidious upkeep.

In contrast, solid wood furniture calls for regular cleaning, oiling, and refinishing to preserve its quintessential elegance, an endeavor that certainly requires financial endorsement. While wood is vulnerable to damage from moisture and environmental pressures, repairs often demand skilled craftsmanship, often imposing labor-intensive and financially significant costs. Such repairs could range considerably, pivoting on the type of wood and damage extent.

Resale value remains a resilient beacon for solid wood, largely due to its quality perception. Well-maintained wood flourishes with a growing resale value, a coveted characteristic that endears collectors and casual buyers alike. Rattan, although appreciated for aesthetics and lightweight pragmatism, doesn’t command the same market reverence. Consequently, its resale potential may falter, especially with signs of wear or elemental impact, tilting investment findings towards solid wood when weighing long-term economic rewards.

Resale value comparison: rattan vs. solid wood

Resale value forms a critical axis in evaluating cost-effectiveness. Solid wood furniture frequently commands a higher resale value, renowned for timeless design, durability, and market desirability. These characteristics ensure that wood pieces retain or even appreciate in value, a tangible asset to those that maintain them impeccably. Consequently, solid wood asserts a financial robustness, encouraging long-term commitment from users anticipating enduring value beyond initial consumption.

In contrast, rattan’s resale value, while favorable for its distinct aesthetic, generally wavers below wood’s echelon. Although rattan captivates the eye, its market value feels the strain from perceptions of lower durability and substantial wear after weather exposure. It can hold allure in design-conscious circles, yet fails to emulate the esteemed legacy that wood achieves. Ergo, potential depreciation represents a layer of risk within the typical life-cycle analysis for rattan investments.

In this rattan versus woody domain, cost structure comparisons expose fascinating interplays between maintenance, durability, and overall cost-effectiveness. While rattan boasts lower upfront costs, its life in terms of longevity may beckon higher expenditures concerning replacement and maintenance, against a backdrop of relatively lower resale viability. Wood, while bearing initial financial demands, emerges with resilience and market value, suggesting formidable returns over extended durations.

Recognizing these financial forces enables furniture enthusiasts and industry stakeholders to evaluate choices keenly, balancing aesthetics with economic intelligence.

Comparative cost analysis: rattan vs. metal furniture

The cost structure and durability factors shift dramatically when contrasting rattan with metal furniture, each bringing distinct financial considerations into focus. Initially, production and manufacturing costs paint a contrasting picture, with metal often benefiting from mechanized processes that can reduce labor input, albeit with higher raw material and energy costs. The resilience and strength of metal introduce a layer of longevity challenging to match, impacting overall cost effectiveness by minimizing repair and replacement intervals. Understanding how rattan’s initial affordability juxtaposes metal’s long-term sturdiness invites nuanced financial evaluations.

Production costs: rattan vs. metal

Production costs commence the dialogue between rattan and metal, illuminating two starkly different financial paradigms. Rattan's organic essence necessitates costs shrouded in ecological sustainability and ethical harvesting techniques, intricately interwoven with nature’s cyclical rhythms. Variable raw material costs, reminiscent of fluctuating seasonal cycles, influence cost structures alongside labor-intensive crafting that lovingly shapes rattan into fine furniture.

Comparably, metal furniture draws from ores as basic material, such as steel or aluminum, with significant variances based on global market indices. While metal production harnesses mechanization for efficiency, which can reduce labor reliance, this manufacturing method punctuates cost discussions with equipment expenses and machinery upkeep, as well as energy consumption.

Skilled labor costs delineate another battlefield where rattan and metal vie for economic supremacy. Rattan craftsmanship demands traditional skill, with artisans deftly weaving and binding natural threads into seamless harmony, fostering higher labor rates. Metal regales with automation potential, employing exhaustive engineering prowess but reducing manual input wherever feasible. Yet innovation and technology bring costs that are reassuringly consistent.

Rattan plays its sustainability advantage as a keystone, establishing itself in eco-conscious circles as a low-carbon, renewable offering. Meanwhile, metal must defend its durability merits, brandishing longevity and resistance without being shackled by environmental soft power. Steel or wrought iron offers resilience against time’s inexorable march, reducing lifecycle replacement frequency attributed to softer materials.

Durability and its impact on overall costs

The impact of durability on long-term costs manifests as a critical differentiator when evaluating rattan against metal. Rattan’s lightweight nimbleness proffers an elegance and ease of positioning unmatched by more steadfast, stalwart counterparts. Yet this portability juxtaposes with endurance, especially when exposed to external perils such as moisture or relentless sun, potentially heralding an audience of repairs or replacements.

In contrast, metal furniture is heralded as a paragon of lasting strength, boasting resistance to inclement weather and rugged treatment alike. While demanding a greater initial outlay, this sturdiness spells financial relief through drastically diminished need for intervention or early discarding festivals. Over the material's lifespan, metal’s resilience remains an economically favorable path as it withstands life's travails unfazed.

The divergent energy paths of manufacturing further elucidate the production quandary. Rattan embraces reduced energy methods, eschewing intensive processing and assembly for simpler, natural travails. This minimalist approach preserves low energy consumption, taming manufacturing emissions a valuable asset in an era cognizant of climate impact. Meanwhile, metal relies on energy-laden processes, prominently featuring mining and refining, to reveal its noble gleaming surface. High-coefficient energy demands cast a shadow over metal, elevating the carbon footprint profile, but frequent innovation and renewable sources counterbalance this to some extent.

Balancing the scales, rattan’s ethical harvesting and inherent simplicity may beckon upon lower lifecycle costs but face potential unknown challenges deriving from wear and weathering, while metal’s upfront cost allegiance bestows preservation of longevity and reduced maintenance, fostering long-term financial advantage.

Energy consumption in manufacturing: rattan vs. metal

Energy footprints in manufacturing delineate another battleground where rattan and metal report contrasting socio-ecological personalities. Rattan’s organic flexibility calls for fewer energy resources, embracing less-intense processes that navigate its transformation from plant to product. This pathway charts a reduced carbon impression, lending itself as desirable beneath sustainable industry paradigms eager for low-energy signatures.

Concurrently, metal processing, dominated by extensive energy requirements, venerates itself upon a platform of industrial magnitude. Extractive mining, intense refining, and formidable shaping of metals imply profound resource engagement, paralleled by cost considerations within the monumental energy bill ledger. Despite these indelible imprints, innovation unveils shifts to renewable energy, cleverly cloaking metal with greener credentials.

Aligning energy consumption prowess with financial acumen, rattan parades low energy costs as a bulwark against metal’s robust durability dominion. Rattan champions reduced manufacturing emissions suggest economic and environmental benefits throughout the lifecycle. On the flipside, metal's higher carbon incumbent role poses challenges that fuel conversation around ecological burden. However, embracing sustainable energy sources within production gradually shifts metal’s perception from industrial liability to economical triumph.

Cost structure comparisons radiate the strategic interplay where rattan’s natural integrity buffers initial cost distinction, offset by maintenance intrigue. Simultaneously, metal triumphantly wears the robustness crown, deriving potential amortized savings from endearing service years unchallenged by nature’s turbulence.

Comparative cost analysis: rattan vs. plastic furniture

In evaluating rattan against plastic, the dialogue shifts towards raw material costs, with plastics offering economic efficiency but presenting environmental and sustainability conundrums. The robust yet lightweight rattan contributes nuanced durability dynamics by virtue of being a natural material. However, its sustainability narrative raises its stature considerably over plastic, carving a trajectory aligned with modern consumer sensibilities and furnishing eco-friendly spaces. In juxtaposing cost structures, rattan engages higher upfront material expenses with aesthetic allure, while plastic benefits from synthetic expediency attractive for mid-tier pricing and rapid production.

Cost of raw materials: rattan vs. plastic

Raw material costs emerge as the vanguard in the scrutiny between rattan and plastic furniture each recounts a different financial story. Rattan materials, procured with dedication to ethical and renewable practices, come bundled with accompanying chemicals and resources pivotal for crafting a quality masterpiece. Monthly expenditures for raw rattan supply highlight industry engagement costs, approximating USD 14,690 in specific market contexts.

Conversely, plastics boast efficiency, employing synthetic polymers derived from petrochemicals and leveraging economies of scale for artful dominance. As crude oil price indices fluctuate, reflecting global market currents, so does the cost of producing plastics. Varying market conditions predicate plastic's adaptive cost efficiency, undergirding the raw material economic narrative with flexibility and mass production prowess.

Exploring cost structure parallels, labor-intensive processing elevates rattan’s initial material stakes, enhanced by its attractive, tangible elegance. This tip of cost is reinforced by anticipated profitability crossing an 18 to 23% profit margin in segmented raw material processing. In contrast, plastic benefits from mechanized production, harnessing methods conducive to faster models and lower labor requisites. These efficiencies impact final pricing beneficially, ensuring that plastic emerges as an accessible option amidst affordability debates.

Market dynamics solicit consumer engagement with rattan’s captivating, eco-friendly narrative, aligning with high-end segments and distinguished spaces. The psychological allure of eco-friendliness provides leverage over mid-tier plastic furniture offerings, which challenge price efficiency but may falter on perception of quality. Notably, plastic’s competition in price-sensitive brackets may satisfy broad consumer palettes, yet rattan appeals to a premium market in search of bespoke and sustainable ensconcements.

Environmental costs and sustainability considerations

As thoughts pivot towards environmental costs, rattan’s sustainability strides confidently forward. Renewably sourced from tropical locales, rattan harbors an immense biodegradability advantage, naturally integrating into ecological systems without unsustainable exploitation, when managed properly. Beneath calm biodiversity, rattan cultivation yields myriad societal gains, promoting local economic empowerment while cultivating ecological vitality.

In contrast, plastic narratives intertwine intricately with environmental predicaments, often voicing concerns about lifecycle effects rooted from production to disposal, impacting natural systems. Limited recycling rates clamor against plastic’s prolific production scale, forgering environmental pollution living beyond acceptable lifecycle confines. While plastics date durability extends under specific conditions, the longer timeline accompanies a weary environmental burdensome albatross.

As consumers evaluate durability, rattan imbued with strength and flexibility demonstrates remarkable adaptability, often maintaining its gaze in outdoor setups safeguarded by thoughtful care. Plastic’s dominance, though resistant to moisture and UV-born woes, may eventually wane with brittleness or fading colors. Financially, rattan investments may surpass initial price tags compared to plastic purchases, yet it often prevails with less frequent replacements and a glimmering environmental appeal. Plastic offset by economic inception reveals costs recurring from short-lived usage, presenting hidden economic implications transferred through iterative replacement cycles.

Durability and its financial implications

Durability terminates the discussion, juxtaposing financial implications centered around rattan’s graceful longevity vs. plastic’s resilient yet ephemeral presence. Rattan elegance, cherished with adequate care, prolongs life significantly beyond a whisper of origin. Its practicality radiates organically, enchanting inquisitive minds with sustainability upheld under patient tending.

Plastic draws resilience in turbulence, fortified to withstand capricious climatic swings with unabashed ease. Nonetheless, decline shadows traits marked by brittleness or chromatic desaturation, projecting uncertainty on enduring investment endurance in the vast majority.

Financially flourishing with vibrant narratives, rattan investments may climb higher compared to fleeting transactions for plastics at the threshold of economic pondering. Yet with a mindful embrace of rattan’s aesthetic life expectancy, long-term costs often subdue inconspicuous plastics, showcasing a tapestry of innate harmonious sustainability.

Constructing the discourse, while plastic’s affordability magnetizes affordability seekers, rattan shimmers under prudent economic purview as a cost-effective, evergreen bastion amid fleeting market currents. This sentiment resonates, ensuring rattan’s gentle virtues crystallize into consumers’ choice for mindful harmonization with nature’s rhythm.

Market trends influencing rattan cost structure

Current ✨market trends✨ increasingly favor rattan furniture, driven by sustainable and eco-friendly movements that elevate its cost structure against competing dynamics in the furniture industry. Connections with global supply chains elucidate pricing fluctuations and underlying economic forces. They relate directly to consumer preferences, which influence rattan production’s financial expectations and strategies. With compelling growth trajectories, understanding these trends illuminates an industry trajectory adorned with sustainability and aligned with evolving consumer sensibilities.

Demand trends in rattan vs. other furniture materials

The uprooted popularity of sustainable materials offers rattan newfound prominence, attracting eco-conscious and style enthusiasts alike. Rattan’s growing demand, seen as both an aesthetic and environmental darling, aligns with burgeoning shifts favoring environmentally responsible living standards. This awareness translates into elevated market demand, creating cascading effects on production scale. Economies of scale ambitions foster potential stability within its cost structures, contrasting uncertain traditional rapids influenced by forest constraints and related scarcity imbues.

Durability and versatility encore thrives in rattan’s resilient design, casting it favorably against conventional furniture materials. Its weather-resistant and indoor-outdoor adaptability entices a crowd seeking multifaceted solutions, capable of harmonizing with distinct domiciles. This durable charm enriches consumer appeal, potentially positioning rattan favorably against plastic furniture, necessitating maintenance adjustments or weary lifespans.

Scrutinizing chemical regulation frameworks, rattan furniture design questions rely on evolving constraints spotlighting restricted substances within conversations about environmental impact. While regulatory burdens can influence processing costs temporarily, these challenges encourage design innovation capable of sustaining competitive vitality. Conversely, synthetic furniture alternatives often benefit from economically liberal chemical perspectives, suggesting reduced financial pressures.

Observing segmentation reveals, rattan spans wide and far across residential and commercial furniture domains, caching diverse appeals within leisure, outdoor usability, and diverse market entries. Differentiated applications reflect nuanced cost structures, where similarities exist across broader materials constrained by foreseeable market orientation limits.

International exchange, notably supported by major producers like China, highlights rattan’s cross-border readiness, evidencing commendable affordability seducing domestic Western marketplaces. Nestled beneath cost-effective sourcing, accessibility breeds competitive buying choices worthy of analysis. Nevertheless, global shipping fluctuations present barriers requiring shrewd strategies to maneuver potential cost increment scenarios for cherished retail venues.

Rattan sidesteps traditional intensity, responding to increasingly demand-oriented preferences embracing relaxed outdoor living arrangements, cultivated for coziness and comfort as a revolt against COVID-19 insulation. This tendency champions diligent pursuit into new, consumer-geared endeavors perceived as warm and luxurious.

Impact of global supply chains on rattan pricing

Rattan’s global supply chain intricacies directly sway cost structures and final pricing, threading connections through geographic arenas of production, disturbance potential, and consumer sentiment. Logistics stalemates, such as those experienced during the COVID-19 pandemic, inflect dramatic pressures on rattan pricing through stock restrictions, shipping inflation, or associated delays reducing consumer confidence.

Counterbalancing challenges, eco-aware inclinations among consumers continue bolstering conditions favorable toward rattan engagement through discernment centered on eco-solutions. Ethical sourcing, prominent in aspirational marketing campaigns, reinforces premium value by imparting intrinsic sustainable partnership qualities, all contributing to higher engagement and uptake amid elaborate sustainability education.

Influence from macroeconomic fluctuations, meticulously embraced, suggests influential factors including inflation concerns, comparing economic shifts, and evolving consumer optimism. As economies flourish, the influx of economic stimuli invites increased rattan acquisition, while economic downturns signify diminished ambitions even within modestly priced products.

A broader comparative evaluation among rattan and other materials positions cost structures, contingent upon supply modality; however, consumer inclination toward organic integrity bolsters rattan’s relative allure. Rattan efficiently crosses competitive pricing spectra, replete with lightweight comparisons yet mindful of labor-intensive procedures. Sustainability grants rattan future appeal atop sustainable priorities guiding the global market forward.

Letting these interactions harvest insight, producers engage cost strategies and pricing maneuvers resonating with consumer desire while nimbly adapting to market trends. Simultaneously, thorough comprehension of these dynamics orchestrates confident sectoral navigation, exemplifying informed and visionary directions to gratify future customer anticipation.

Consumer preferences and their economic effects on rattan production

Consumer preferences dramatically transition how economic enigmas unfold within rattan production. The once-persisting demand ceiling transcends bounds, manifesting a novel iteration of request levels, lofting sustainable products beyond the ethics realm into aesthetic engagement.

As awareness mounts, sustainable product adherence translates into essential rattan appeal to ESG-conscious consumers. The ubiquitous virtue of natural fiber drives manufacturers to innovate while naturally imbuing environmentally-resilient approaches. This repositioning establishes rattan amid au courant creations genuinely influenced by pressing worldly matters.

Navigating market variability, producers adapt studiously, thus anticipating demand changes influencing production levels, translating to economic advantage through strategic production breadth adjustments and deliberate brand narrative revisioning. As selective buying spirits maximize potential, aligning with this consumer engagement furnishes rattan’s pool with incentives worthy of exploration.

The supply chain stability underpins response formations, emulating adaptive shifts, calling forth efficient international logistics harmonization, fertilizing on-time delivery reliability and amplifying rattan’s charm through timely market influence.

Cost structure comparisons invigorate, rattan brand positioning against incumbents situated within broader material domains, rendering comparative sustainability aspirations. When visionaries mix branding vigor with economic acumen, allure pervades designs, persuading consumers effortlessly ensconced within tactile ambiance and artistically sustainable pursuits.

Finally, these analyses forge illuminating pathways guiding leaders through determined branding amidst wrought consumer resonance, serving to reintegrate broader appeals across diverging lifestyles and parametric choices animated by evolving consumer biases.

Case studies and real-world examples

The vibrant narratives of case studies and real-world examples expose the interplay of financial performance within the thriving rattan industry, signifying creative strategies and success milestones. Rattan brands represent victory through innovation, sustainability, and determined craftsmanship bringing forth lessons that harmonize cost structures with compelling brand offerings.

Financial performance of rattan-producing companies

Employment of economic studies informs the profit potential among theatrical comparisons between core components and refined outputs. Rattan's untethered financial trajectory exhibits profitability brackets around 16.5% to 23%, capturing semi-separated optics of processing, whether core manufacturing or artifact crafting.

One poignant breakthrough entails Permacane introductions, revolutionizing design scope through building precision engagements, amplifying organic value beyond normative constraints. Rattan variations enhance with diversified applications, yielding an outlook unparalleled within restrictive hardwood limitations. Intriguingly, rattan often intersects with lower material requisites congruent to traditional wood, reducing capital needs while facilitating commercial ascendancy.

Carving fitful contributions within regional and global implications, case studies reveal potent impacts, such as within the Philippine sector, advocating economic resilience alongside local benefits through amplified employment generation. These initiatives juggle industry adaptability within lower investment needs, unlocking opportunity trajectories aligned toward competitive transformation.

Conclusion: key takeaways from cost comparisons

The focal essence of cost comparisons crystallizes as a multifaceted discourse where thematic distinctions envelop rattan furniture against the vivid backdrop of other materials. The summary of cost advantages emphasizes rattan's lightheartedness and conscientious persona fostering markets rooted in sustainable curiosity, with economic capacity symbolically juxtaposed against the backdrop of modernity.

Summary of cost advantages of rattan

Casting light upon rattan’s cost structures reveals a symphony marked by sustainable tenacity and affordability harmonizing across nuanced design realms. Beyond the initial exuberance, through discerning inquiry into maintenance, replacement costs, and environmental considerations, the core becomes solidified, gaining firm support beyond boundaries indelibly etched in tradition.

Cradled beneath rattan’s bespoke character, it flutters amid reinforcing systemic functions. Although defined by comparative resilience, wood and alternative synthetic facets harness durability heartily, frequently long-hauling resilience exceeding competing narratives laden with wear. Through a labyrinth contrast, intricate dynamics lead to reduced costs due to lightness, renewable harvest cycles, and production nuances.

Future outlook on rattan vs. other materials in the furniture market

Surveying the grand expanse, rattan’s formidable future is inscribed among market ambitions unshackled by rigid convention, unexpectedly illuminating benchmarks where sustainability coalesces, and consumer affection aligns. Through competitive cost structure oversight, rattan enters deployment realms emphasizing growth and transformation through harmony found within its assorted material troves.

Closing

In closing, from discerning rattan’s fixed and variable costs through comparative longevity, an enlightening inquiry guides understanding of the reticent, welcoming embrace within the furniture realm. Whether framing cost-effective allure of sustainable highlights, seeking lower initial expenditures, or verifying long-term worth, rattan insinuates ecosystemic integration, an embrace product of deep commitment inherent. Carefully threaded throughout ecosystems, rattan flows across the global furniture stage-one marked by thoughtful unity through timeless economic dialogues.